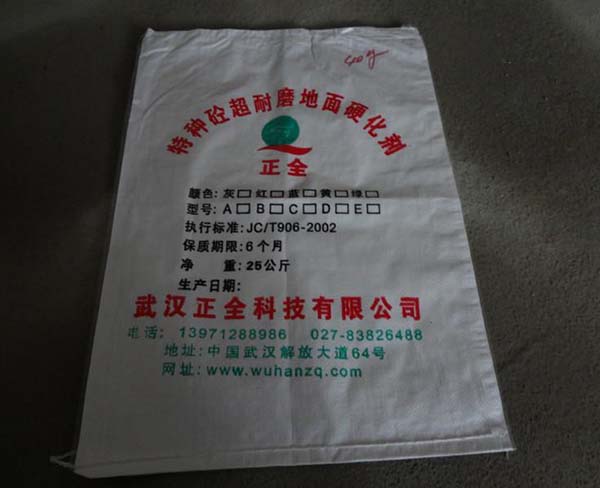

Analysis of the production process of Hefei woven bag

Mold selection

Mold is the key to the production of woven bags, according to the type and use of woven bags, choose the right mold is the premise of the quality of woven bags. The choice of the mold needs to consider the size, thickness, strength and other factors of the woven bag.

The production process includes the heating and plasticizing of the woven bag mold, the molding of the woven bag mold, the traction and shaping of the woven bag, and the cooling and packaging. In the production process, it is necessary to pay attention to the control of temperature, pressure, traction speed and other factors to maximize the quality and output of woven bags.

The quality control of production includes the quality control of raw materials, the quality control in the production process, the quality inspection of finished products, etc. It is necessary to establish a sound quality management system and conduct regular quality testing to ensure that product quality meets national standards and customer requirements. Five, environmental protection treatment

Hefei woven bag production process will produce waste gas, waste water and solid waste, need to take corresponding environmental protection measures, such as waste gas treatment equipment, waste water treatment facilities and waste residue recycling, etc., in order to reduce pollution to the environment. Summary: The production process of Hefei woven bag includes raw material selection, mold selection, production process, quality control and environmental protection treatment. In the production process, the quality and environmental protection standards of all links need to be strictly controlled to ensure product quality and environmental protection.